increase your quality control

SMART IN-LINE SENSORS

Our Smart In-Line Sensors can help you develop a more efficient production line in the best way possible, by recreating the product in your line, and with a design that makes our sensors travel and record everything without the need to stop or reduce speed of the line.

The Voyager Concept

High technology standarts

Modular technology / Firmware update / Connection with app Voyager Connect

Analytics & Insights

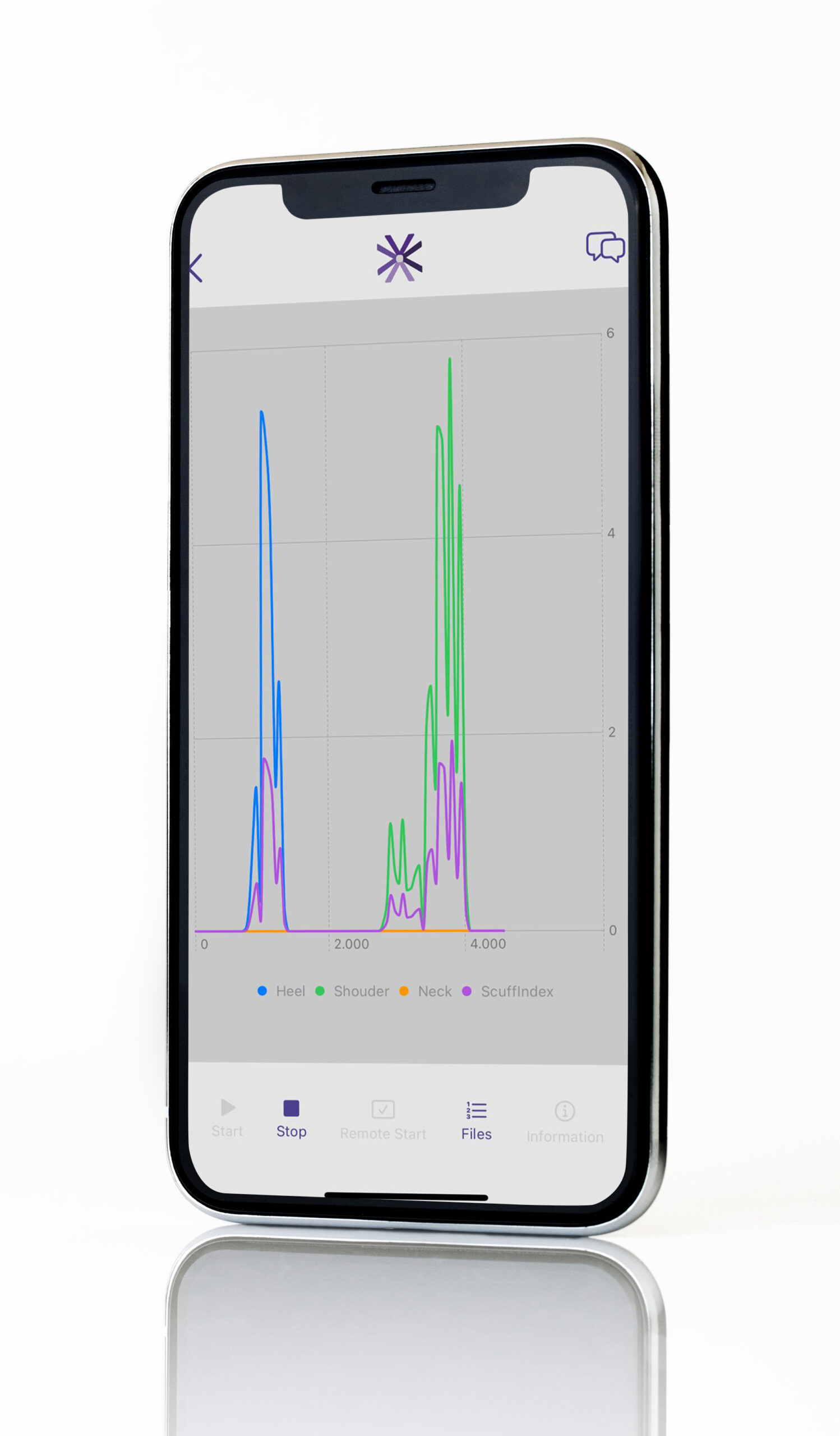

Access Measurements in real-time / Interactive View / Start - stop command / Available at App Store

Cloud Integration + data security

Access Measurements with Cloud Integration / Access - data control / Data export

Our Products:

The VGR Load Series offers an in-line measurement with real-time data of the force applied from the seaming heads. Thus measurement is made in a 360° seaming edge with a high rate of data.

With the VGR Force you can measure the correct vertical force throught the closure process in real-time and speed. All your data can accessed localy ou remotly in any device

VGR IMPACT

The VGR Impact Series offers precise control of the scraping rate due to the lateral membranes, in addition to being able to measure the angle of the bottle, ensuring an increase in their useful life and number of filling cycles in the same glass bottle.

With the VGR Pressure you can measure the pressure between -0.8 and 5.0 bar (-12 to 72 psig) and speed superior than 10 measurements per second without losing grafic details.

Advantages of the Voyager Smart In-Line Sensors:

- Cloud integraton (AWS)

- Non-destructive and non-invasive measurements

- In real-time measurements

- Designed on request according to customers’ drawings

- With our product you have more precise and quick analysis;