increase your quality control

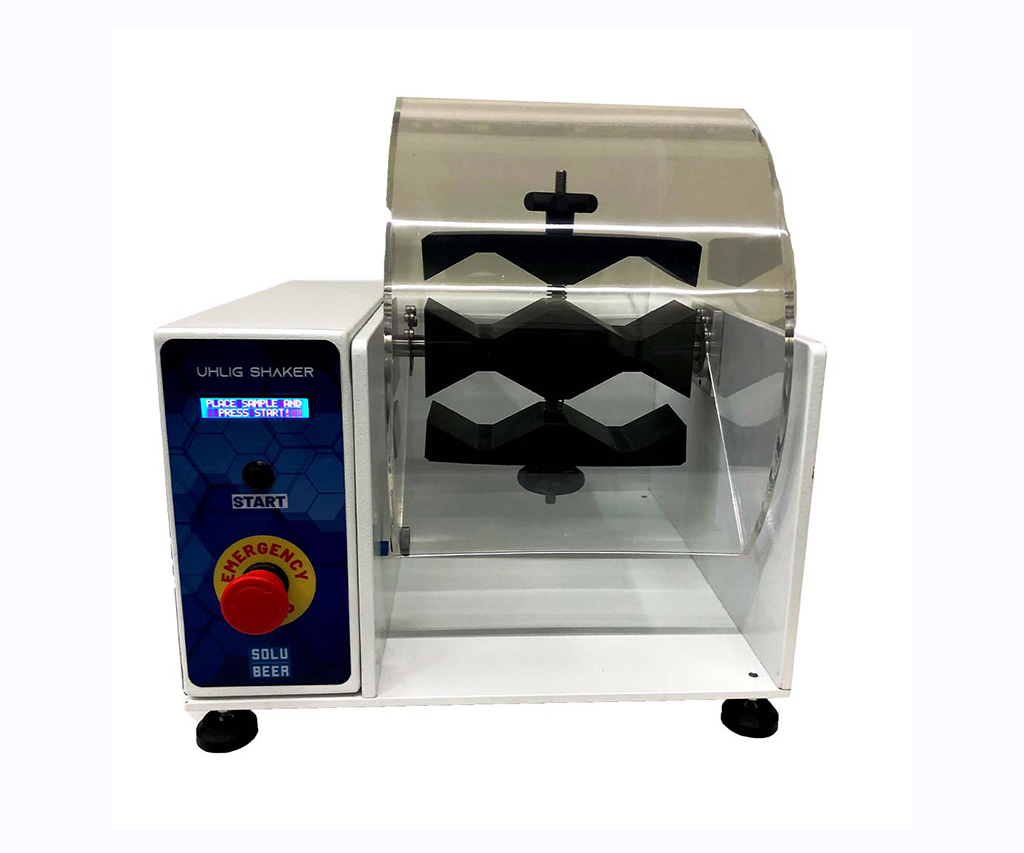

Uhlig Shaker

The Uhlig Shaker equipment is used to perform TPO measurements in samples using the method uhlig that asks to shake 5 minutes at 40 RPM and rest for another 5 minutes after shaking.

Technical Information:

- Engine rotation: 40rpm/m;

- Dimensions: H=45x L=40X L= 40;

- Inductive safety sensor to drive only with the doors closed;

- Emergency button;

- NR-12 acrylic protection;

- Microcontrolled counter with alarm;

Our company is determined to develop and find new technologies to solve problems frequently faced by Food and Beverages industries, and provide solutions to improve it´s lifespan and reliability. Improve your final-products quality with our solutions!

Benefits:

- Low maintenance;

- Reduction of product loss;

- Low cost investment;

- Less work volume;

- For all sizes os bottles and cans

Aplication:

In beer, soda, wine labs, after the production, you need to shake up to 4 simultaneous samples of any size

Scope of supply:

- Uhlig Shaker

- Instruction manual

- Energy cable